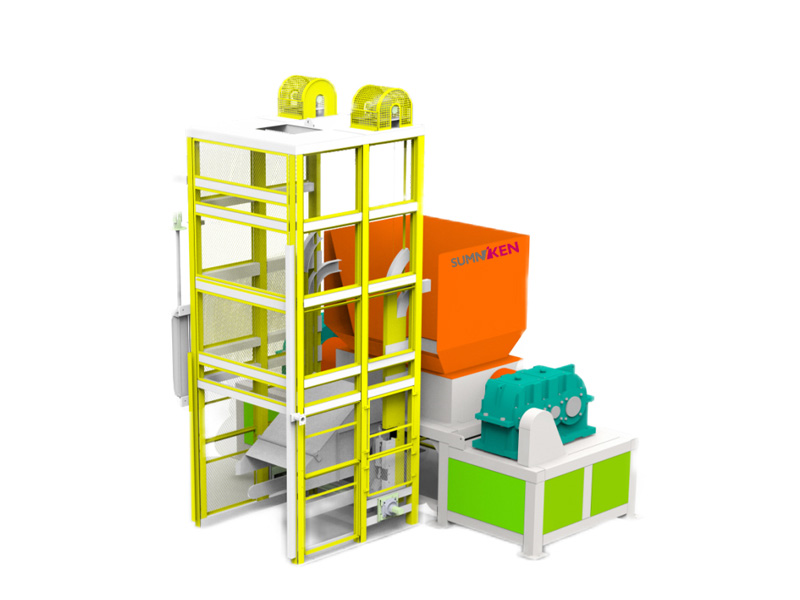

A special equipment designed for crushing and returning NG die castings to the furnace. It is forged with special alloy tool steel, precision machined, and after multiple heat treatments, the hardness reaches above HRC53-55°, with long service life, strong cutting ability and high productivity.

Driven by dual motors and hard-tooth surface reducers.

Driven by dual shafts independently, so that during production, the materials are pressed accordingly to achieve automatic feeding function.

Adopt PLC programmable control with high automation.