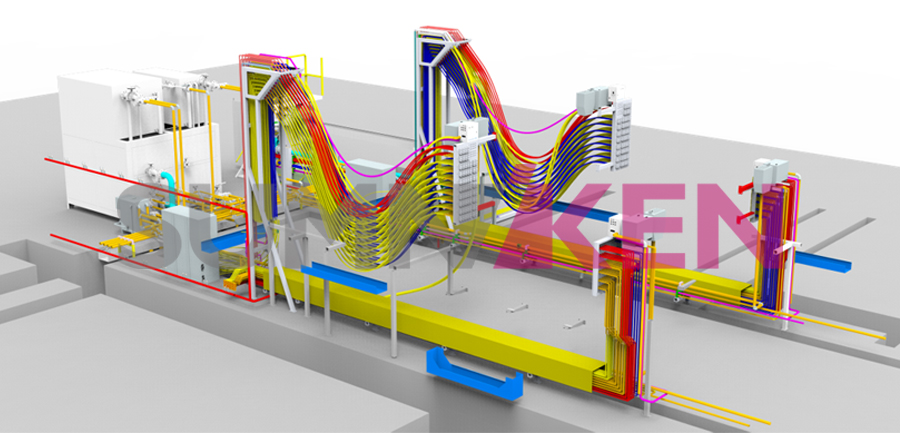

Integration of the entire liquid medium pipelines such as mold cooling water pipelines, mold temperature machine hot oil pipelines, and high-pressure point cooling pipelines. Due to the complexity of the pipeline system, it should be designed and implemented as required.

1.Use precision-rolled seamless bright tubes.

2.Our company will connect all hot oil pipelines and mold cooling water pipelines with ferrule fittings, all of which are made of stainless steel. 45-degree and 90-degree fittings are used at the hanging positions of the hose assemblies, and stainless steel ferrules are preferably PARKER or German GS.

3.Pipeline heat insulation: use fireproof and heat-insulating ceramic fiber cloth or ceramic fiber sleeves instead of glass fiber cloth. For stainless steel pipe protection, imported fireproof pipes can be selected (they will not deform or embrittle when burned with an open flame).。

4.Fixed method for hot oil pipelines and cooling water pipelines: use aluminum heavy-duty pipe clamps instead of U-shaped clamps and P-shaped clamps.

5.For the outlet part of the mold temperature machine, the hot oil hose assembly is anti-scald treated, and the cooling water inlet and return assembly adopts EO joints.